The Industrial Revolution 4.0 and How Mitsubishi Electric's Participation

In recent years, the concept of the Smart Factory or Industry 4.0 has become increasingly popular and has become the development goal of businesses in the industrial manufacturing sector. This is seen as a major Industrial Revolution, notable for the integration of various technologies such as the Internet of Things (IoT), cloud data analytics, and artificial intelligence (AI) applied to the manufacturing process.

In Vietnam, manufacturing enterprises are also striving to apply AI-enabled devices to optimize production processes, reduce maintenance costs, and improve product quality, creating new development opportunities and enhancing competitiveness in the market.

Mitsubishi Electric is at the forefront of participating in the 4.0 revolution with the integration of various advanced technologies, notably the Maisart AI technology - a compact AI software applied across many of the company's devices.

*Maisart stands for "Mitsubishi Electric's AI creates State-of-the-Art technology," which is the brand name of Mitsubishi Electric's AI technology.

Applications of Maisart and its unique integration with Mitsubishi Electric Robots

Mitsubishi Electric's AI Maisart easily integrates into various devices and applications to provide intelligent features and optimization for users.

- Identification/Recognition: Capable of accurately identifying/recognizing specific objects, humans, or locations.

- Cause Determination: Identifying abnormalities in the production process and quickly and accurately determining their causes.

- Abnormality Prediction Capability: Signs of abnormality are detected from data collected during normal operation, helping prevent issues before they occur.

- Optimized Control: Optimal control methods are formed using collected operational data, helping to optimize operations more efficiently.

- Automation: Processing using various sensors enables automatic operation with a level of recognition, identification, and integration beyond human capabilities.

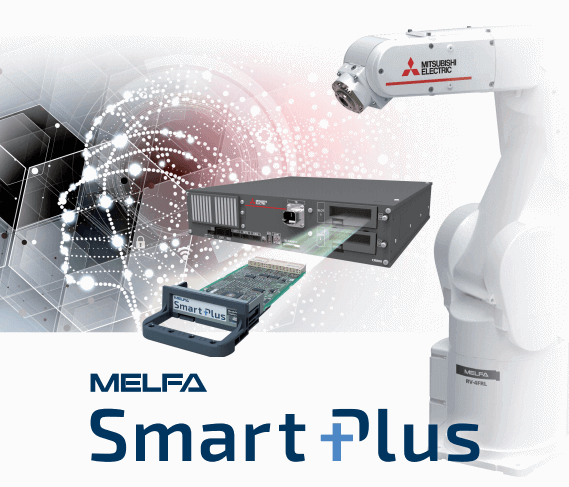

Maisart AI technology is deployed on Mitsubishi Electric's FR series robots through the MELFA Smart Plus card, enabling Mitsubishi Electric robots to possess intelligent features and lead in optimizing production processes.

Self-adjusting force control to grasp and release quickly and accurately, thereby optimizing performance.

Self-adjusting force control to grasp and release quickly and accurately, thereby optimizing performance.- AI learning capability and integration of 2D/3D image sensors help robots perform tasks skillfully, intelligently, and flexibly.

- Automatic calibration and easy integration with control systems help engineers easily set up, optimize setup time, and reduce programming costs.

- Automatic predictive maintenance capability helps the system operate stably, reducing maintenance costs.

Integrating Maisart AI technology through the MELFA Smart Plus card on Mitsubishi Electric robots marks an important step in the Industry 4.0, helping businesses enhance competitiveness and breakthroughs in the digital transformation era. Mitsubishi Electric is proud to be a solution provider and a reliable partner in supporting businesses in building smart factories.