Guiding you to digital manufacturing success

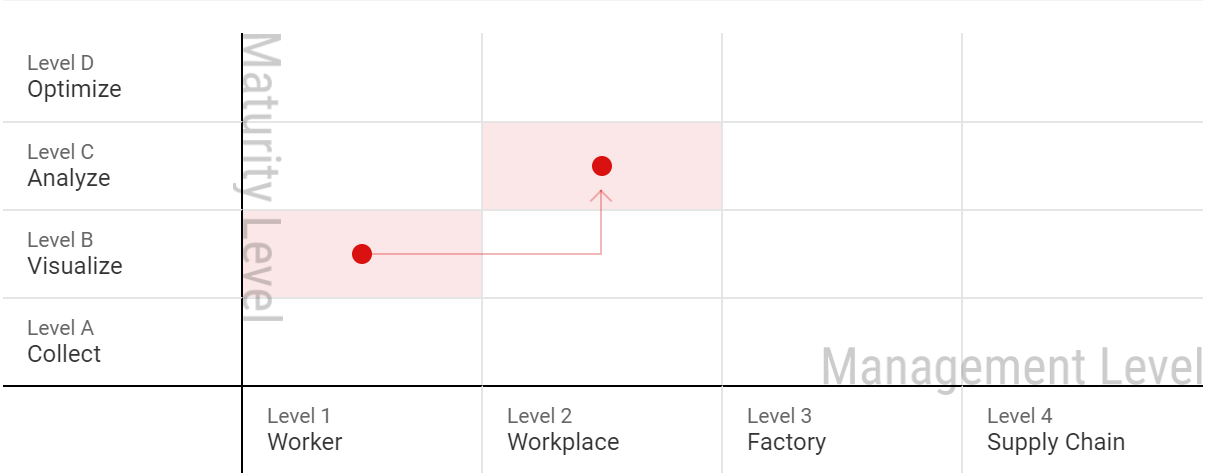

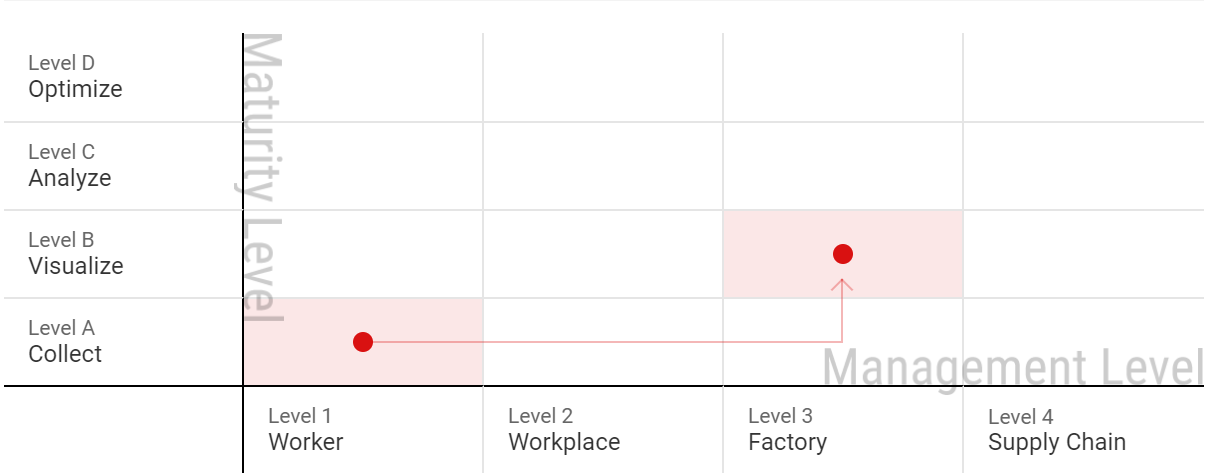

SMKL is an evaluation index of the level of data utilization in factories. It can help management to make investment decisions by showing the purpose, impact and relationship of each investment step towards making your factory smarter.

SMKL evaluates the level of digital manufacturing by using two axis: one is maturity level and the other is management level.

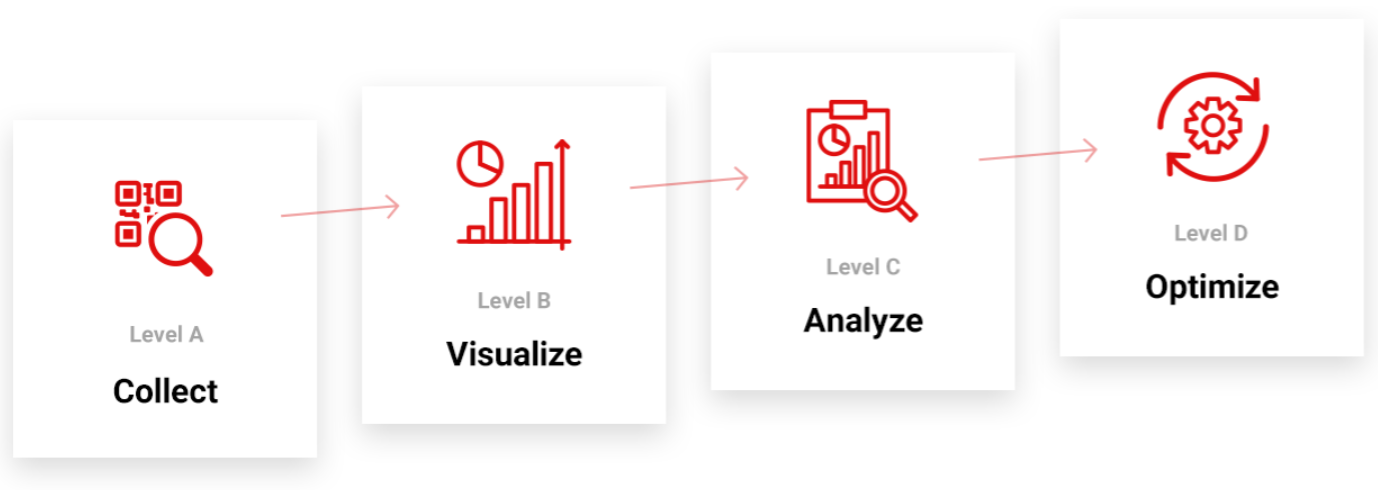

Maturity Level; The level of visibility

The level of data visibility is represented by the maturity level, shown on the vertical axis of the SMKL model. Level A is defined as “Data collection” ; Level B as “Visualization” ; Level C as “Analysis” ; and Level D as “Optimization”.

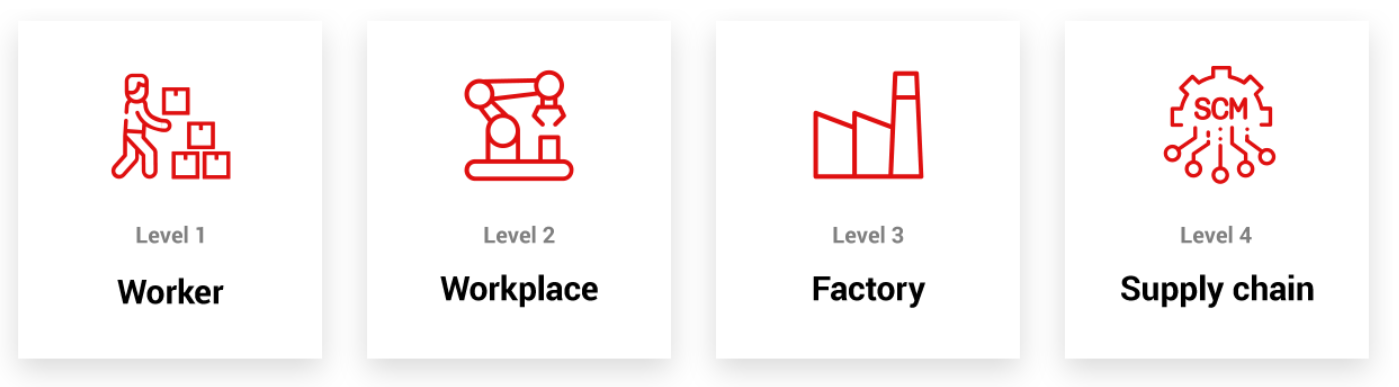

Management Level; The granularity of the items to be managed

The horizontal axis represents the granularity, or level of detail for the items to be managed. Level 1 is defined as the company’s “Worker”; Level 2 as “Workplace”; Level 3 as “Factory”; and Level 4 as “Whole supply chain”.

The value of SMKL

- Start “smartification” from the most appropriate point according to the current level and goals of each factory.

- The modular approach lets you carry out “smartification” step by step.

- Calculating and measuring the ROI achieved at each step is essential for investment decisions.

- Optimization can occur at every level, all the way up to the entire factory and the whole supply chain, leading to significant business improvements (tackling a variety of management issues).

----------

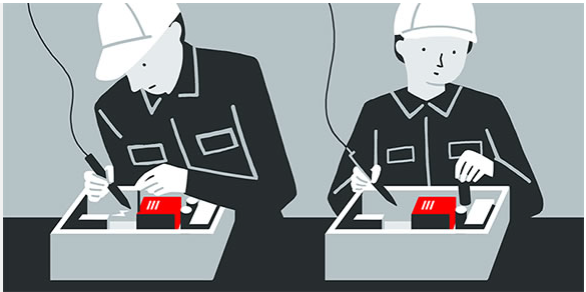

Improving production efficiency, by minimizing variations in worker performance, through "visualizing" operations.

Results

Overall production efficiency increased by 30%.

- Training time for workers reduced by 65%

- 18% faster production switchover between models

- Assembly time reduced by 12% on average

|

Issue Low production efficiency and uncontrollable cost management

|

|

ImplementationIntroduce support tools for the assembly process to the workplace

|

|

ImprovementsSignificant cost reductions by improving worker efficiency through minimizing operational mistakes

|

|

Based on this result, we will realize overall cost reduction by expanding the investment target to the entire factory.

----------

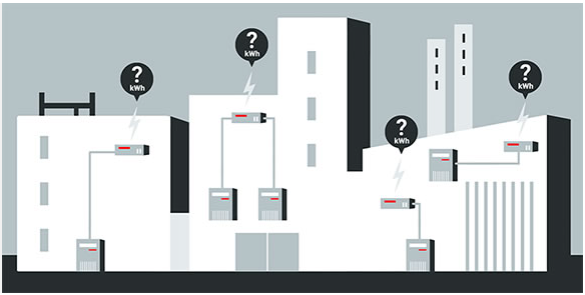

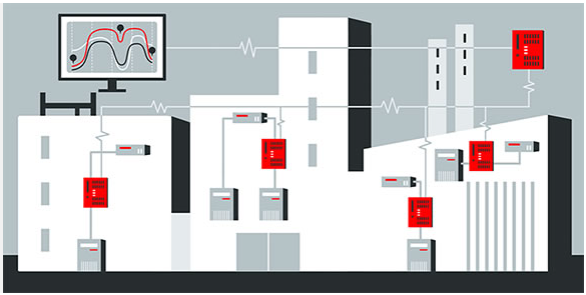

Understanding power consumption and reducing costs through energy saving measures.

Results

Energy saving approx. 800,000 yen/year.

- Investment amount (for system introduction): 2,000,000 yen.

- Payback less than 30 months.

|

Issue High power consumption and running costs

|

|

ImplementationMeasure energy use on each line and piece of equipment, and visualize on a dashboard |

|

ImprovementsSuccessful control of energy consumption

|

|

Based on this result, an overall cost reduction was achieved. The change will now be applied to the entire factory.