Mitsubishi Electric’s Factory Automation Solution Center in Hanoi

Mitsubishi Electric Vietnam cooperated with BKT Joint Stock Company to establish the first Factory Automation Solution Center (FASC) in the North.

The center was founded to introduce technology solutions from Mitsubishi Electric and serve the purpose of research, training, and implementation of technical support activities for businesses in and outsite of the Northern region.

Factory Automation Center in BKT Company, Hanoi.

Factory Automation is the application of automatic control systems, such as computers and industrial robots (robot arms, collaborative robots) to control machines, as well as operate the manufacturing process automatically, with minimal human help.

Various positive changes have been proved when businesses applied factory automation in their manufacturing system, such as:

- Increase productivity: Automated production lines can operate at a constant speed, unattended, 24/24 - therefore the quantity of products made will be higher compared to businesses that do not apply automation.

- Increase quality: With the help of accurately programmed equipment, there is a significant reduction in product error compared to manual processes.

- Increase business competitiveness, increase flexibility, reduce labor cost and many other costs.

As a result, the demand of the automation industry in Vietnam is growing quickly, as businesses have realized the importance of automation in enhancing competitive advantages.

At FASC, Mitsubishi Electric Vietnam applies the smart factory solution e-F@ctory and displays many innovative models of industrial automation equipment:

- e-F@ctory is the optimal production management solution, integrating the control system by IoT (Internet of Things) technology. After connecting all the equipment involved in the process of development, production, logistics, etc,, the Internet system integrated in the e-F@ctory together with the computer center are responsible for conducting analysis and feedback, so that the manufacturers can control the factory remotely via smartphone, tablet or laptop.

- System of equipment for production in the factory from field level to control level (Motor, Inverter, GOT, PLC, redundant PLC).

- Highly reliable electrical system for factory (ACB, MCCB, MCB).

- Energy consumption monitoring system with an error rate of only 0.1% (Multi Meter, EcoWebServer, EcoAdvisor).

- Conveyor system for production.

|

|

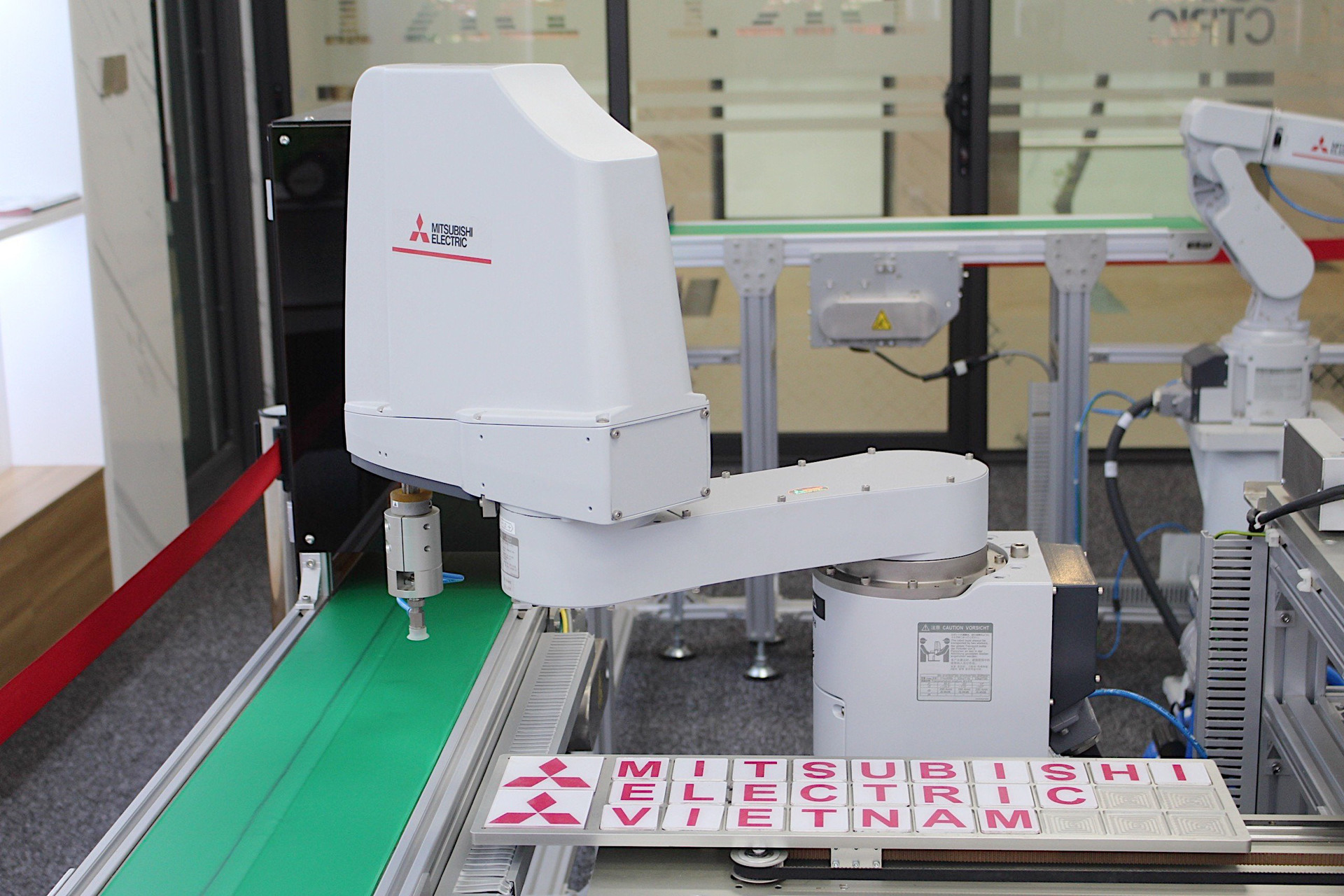

Demo kit of Robot solution integrating Servo motion control system to lift, assemble and pack products.

Industrial network CC-Link (IE-TSN, IE Control, IE Field, IE Field Basic, CC-Link ver. 2.0) and Servo system controller network MELSEC SSCNET.

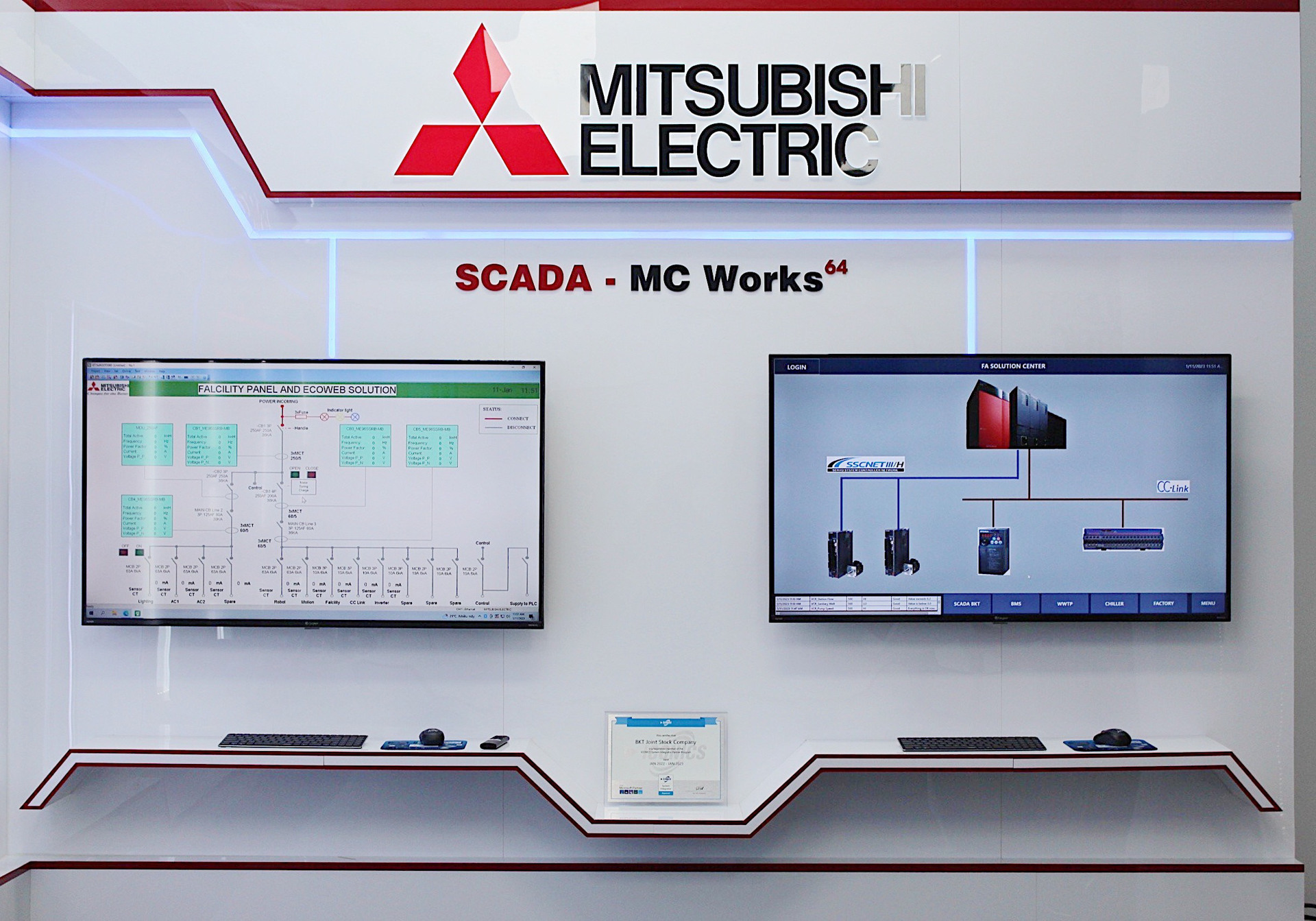

SCADA Software – the solution for system monitoring and process control, which allows many devices and prodution lines to be linked in one platform. It also extracts real-time data, report and diagnose possible risks effectively.

Safe and economical power distribution panel and control system monitor panel from Mitsubishi Electric.

With the goal of supporting manufacturers and customers whose demand for automatic technology and helping engineers who are working at the equipment manufacturing units, FASC Hanoi acts as a bridge to connect them to the advanced technologies, solutions, and equipment from Mitsubishi Electric brand.

Visit to experience our Factory Automation Solution Center at:

Address: BKT JSC., No. A21, Lane 11 Huy Du Street, Nam Tu Liem, Hanoi.